Prefabricated homes are becoming popular as people look for faster, cheaper, and greener ways to build. This article explores how are prefabricated houses constructed from start to finish. Learn about the materials, the building process, and why this method is changing the future of housing. Keep reading to find out how it all works.

What are Prefabricated Houses?

Prefabricated houses, also known as prefab homes, are built in sections at a factory and then assembled on-site. These homes are made using modern techniques that allow for fast, efficient construction without sacrificing quality. Unlike traditional homes built entirely on-site, prefab homes use pre-made parts, making the process more controlled and cost-effective.

The demand for prefabricated homes is growing quickly. People are choosing them for their affordable price, eco-friendly materials, and faster build times. With flexible designs and various customization options, prefab homes are a smart choice for modern living. In this article, we’ll explore how prefabricated houses are constructed, what they are made of, and how prefabricated houses are made. You’ll learn the full process in three clear sections from factory to finished home.

What Are Prefabricated Houses Made Of?

Prefabricated houses are built using strong, efficient materials chosen for durability and sustainability. The choice of materials often depends on climate, cost, and local building codes.

- Structural Frame Most prefab homes use steel or timber frames for strength and stability. Steel offers excellent resistance to pests and fire, while timber suits lighter, eco-friendly builds. The type of frame often depends on local weather and seismic safety rules.

- Roofing Materials Prefab roofs are usually made from metal sheets, asphalt shingles, or concrete tiles. These materials are weather-resistant and easy to install. In colder climates, insulated roofing panels help keep homes warm while reducing energy use.

- Wall and Floor Panels Walls and floors are constructed from insulated concrete, plywood, or wood-aluminum composite panels. These materials help keep the home energy-efficient and structurally sound. Their use depends on the need for insulation and strength.

- Interior Finishes Interior sections include drywall, PVC panels, and laminate or tile flooring. Builders use low-VOC paints and sustainable materials to support healthier indoor environments. This also reduces the home’s carbon footprint.

- Insulation and Sustainability Prefab houses use foam, fiberglass, or natural wool insulation to improve energy efficiency. These materials are selected based on climate needs and green building standards. Choosing eco-friendly components shows how are prefabricated houses constructed for long-term sustainability.

Understanding what are prefabricated houses made of helps us see how thoughtful material choices support faster builds, lower energy use, and longer-lasting homes.

How Are Prefabricated Houses Constructed: From Factory to Foundation

Prefab home construction is a smart, step-by-step process that combines the speed of factory work with the precision of on-site assembly. This entire process highlights what prefabricated houses are made of and how prefabricated houses are made efficiently without compromising on quality or safety. Let’s walk you through it so you know exactly what to expect.

- Design and Engineering Phase What do you want your dream home to look like? This is where your ideas come to life. You’ll work with designers and engineers to create a custom plan that suits your lifestyle and meets all safety codes and local climate needs.

- Factory-Based Construction Once the design is ready, your home begins taking shape in a modern factory. Skilled teams build your walls, floors, and roofs in sections. Every part is crafted with care to ensure quality and consistency. This is how are prefabricated houses constructed quickly without cutting corners.

- Transportation to the Site Once completed, sections are safely packed and loaded for delivery. Trucks or other vehicles carry them to the final location. Careful transport ensures that nothing is damaged along the way.

- Site Preparation Before the building begins, your land needs to be cleared and leveled. Furthermore, make sure that all essential utility connections like electricity, water, and sewage are ready to be fixed. A solid, ready foundation is key to long-term home stability.

- On-Site Assembly and Installation At the site, you can join the sections to form the full house. Crews secure the walls, roofs, and floors quickly. This is where you see how prefabricated houses are constructed into a complete structure within days.

- Finishing Touches After assembly, you can install flooring, paint walls, and connect systems. Final details include plumbing, lighting, and interior finishes. At this point, your home will be ready for you to move in.

This entire process highlights what are prefabricated houses made of and how prefabricated houses are made efficiently without compromising on quality or safety.

Advantages and Innovations in Prefab Construction

Wondering why more people are turning to prefab homes? There are some big advantages to choosing this method, starting with time savings. Since most of the work happens in a factory, weather delays and on-site surprises are greatly reduced. That means your home can be ready in weeks instead of months.

Another major benefit is cost efficiency. With controlled production and reduced labor costs, you can get a high-quality home without overspending. Plus, fewer material errors and less waste mean better value for your money.

Eco-friendliness is also a big draw. Factories use precise material planning, which cuts down on excess waste. Many prefabricated homes also use energy-efficient materials and systems, reducing your long-term environmental impact.

When it comes to customization and scalability, prefab homes have come a long way. You can choose layouts, finishes, and add-ons that fit your needs perfectly. Whether you want a compact home or a multi-room setup, prefab makes it flexible.

Curious about how are prefabricated houses constructed with today’s tech? Innovations like 3D printing now allow walls and components to be created even faster and with greater design freedom. Smart home integration is also becoming standard, letting you control lighting, temperature, and security systems with ease.

As you can see, learning how are prefabricated houses constructed opens the door to exciting new possibilities in homebuilding. From faster timelines to advanced technology, this method keeps evolving to meet modern needs.

Conclusion

Prefab construction offers a fast, efficient, and eco-friendly way to build a home. You’ve now seen how are prefabricated houses constructed from smart design and factory-based precision to quick on-site assembly. With benefits like time savings, cost control, and custom features, prefab homes continue to rise in demand across the world.

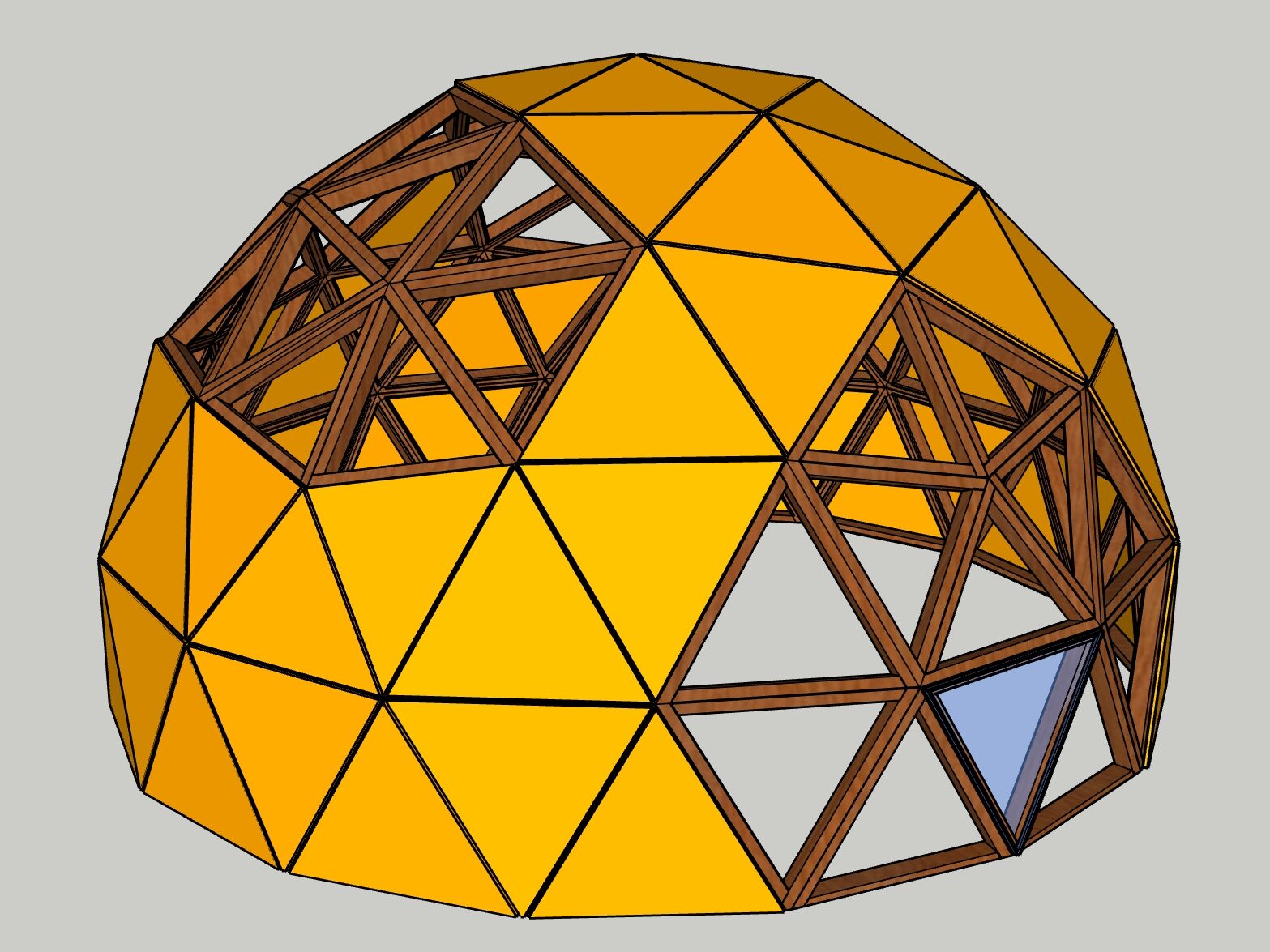

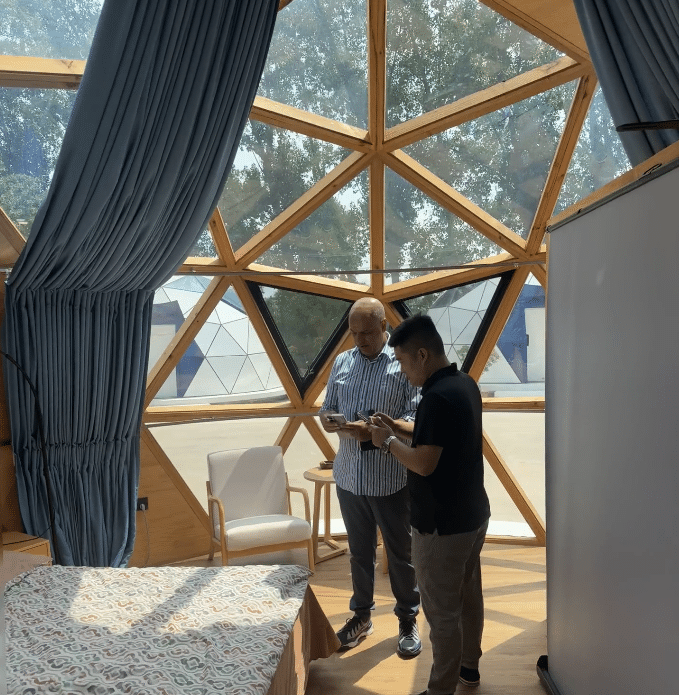

If you’re looking to buy a prefabricated dome house, Capsule Castle can bring your vision to life. We offer single-deck and double-deck capsule homes that suit every lifestyle. Our space capsule houses can be installed on any terrain, whether it’s a mountain, forest, or beach. With a modular design, fast shipping, and easy building block assembly, you’ll enjoy convenience without compromising on quality.

Capsule Castle’s sleek design includes 360° panoramic windows and a unique wood-alu-clad exterior, blending the warmth of wood with the durability of aluminum. These high-end features attract global buyers looking for modern, sustainable living.

Ready to build your dome home? Contact Capsule Castle today and start your journey with a home that fits your world.